EPDM

- Home

- EPDM

Epdm what is EPDM?

EPDM is an extremely durable synthetic rubber roofing membrane (ethylene propylene diene terpolymer) widely used in low-slope buildings in the United States, Canada and worldwide. Its two primary ingredients, ethylene, and propylene are derived from oil and natural gas. EPDM is available in both black and white colors and is sold a broad variety of widths and length, ranging from 10×100, 20×100, 30×100 feet to 50×100 feet, and in three thicknesses, 45,60 and 90 mils (most required is 60 mil). EPDM can be installed either fully adhered, mechanically attached, or ballasted, with the seams of the roofing system sealed with liquid adhesives or specially formulated tape.

The Ballasted System

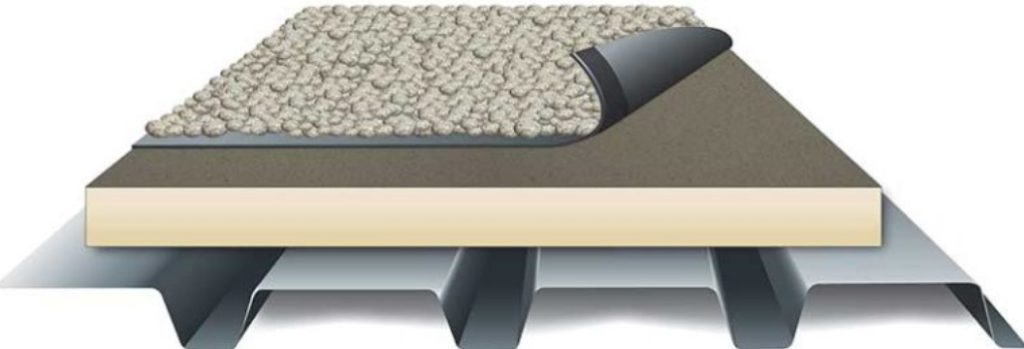

The Ballasted Systems, the workhorse of the three EPDM roofing systems, account for approximately 35 percent of EPDM installations today. Using large panels measuring up to 50 feet by 100 feet, the ballasted system provides fast coverage at a relatively low cost.

The EPDM panels are loose-laid over the insulation and held in place by smooth, river-washed stoned or concrete pavers. Ballasted systems are primarily used for large new construction projects but can also be used on roof replacement or recovery projects where the existing structure can support the additional weight.

Ballasted systems are traditionally the easiest of all systems to install and have earned the Underwriters Laboratories Class A rating.

The Mechanically Attached System

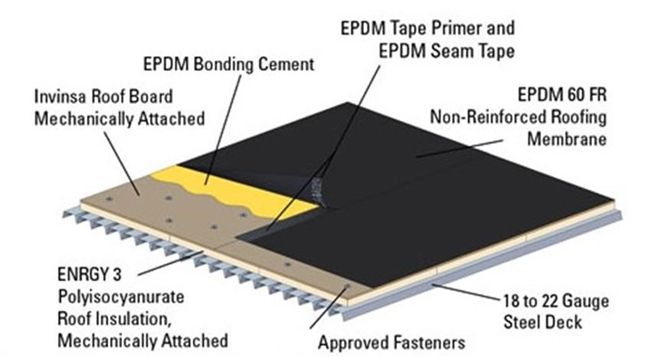

Mechanically attached systems can be installed using large panels and attached through the membrane, or using narrow panels attached in the side laps. Nonreinforced or scrim reinforced membranes can be used, depending on the needs of the building owner. The membrane is then attached using round plate of batten strips to the underlying deck. Mechanically attached systems are lightweight and are ideal for all building sizes and configurations.

The Fully Adhered System

Fully adhered systems using panels measuring up to 30 feet by 100 feet. The membrane is bonded to the insulation, which has been physically attached, utilizing mechanical fasteners, stress plates and/or adhesives. Either non-reinforced or scrim reinforced membrane can be used, with the non-reinforced membrane making up most adhered installations.

Fully adhered systems are lightweight and ideal for a wide range of building sizes and geometric configurations, including high-slope applications. Because of recent technological advances in application, the fully adhered system is becoming the system of choice for roof replacement applications in many areas of the country.

Why EPDM?

The EPDM (ethylene propylene diene terpolymer) rubber roofing membrane has been an appealing choice of the low-slope commercial roofing industry for over 40 years. EPDM continues to be a top choice of architects, roof consultants and contractors for both new construction and replacement roofing projects.

The greatest test of any construction material is how it performs under actual field conditions. Forty years of empirical experience in field applications has shown EPDM to have the roofing industry’s longest average service life. Characteristics that contribute to this superior overall system performance include:

- Cyclical membrane fatigue resistance

- Proven hail resistance

- High resistance to ozone, weathering, and abrasion

- Flexibility in low temperatures

- Superior resistance to extreme heat and fire

- Thermal shock durability

- Ultraviolet radiation resistance

- EPDM’s high resistance to wind damage has also proven to be an increasingly desirable attribute.

- These roof systems can be designed to meet a variety of wind uplift criteria from Factory Mutual, including 1-60, 1-90, and 1-120 ratings and greater, and the stringent code of Dade County, Florida.

- Architects, roof consultants and contractors have come to depend on EPDM’s time tested, long-term performance.

Please note that EPDM is a commercial roofing product, designed to be used in non-residential roof systems.

Our Services

We always stand behind our work, with customer satisfaction being our #1 priority.

Why Choose Us?

100% Safety

My Cons Ltd. places the utmost importance on safety - safety of our employees, the public and of the entire project.

Always On Time

Every aspect of every project is properly planned, equipped and staffed to ensure speedy and efficient completion, on time and on budget.

Quality

In delivering a quality result, no detail is too small and nothing is overlooked. We use top quality materials and employ the most skilled technicians to meet and exceed your expectations.

Experienced

The entire team at My Cons Ltd. is experienced, skilled, and responsive to all of your questions and requests in all phases of the project.

Professional

We are professionals. This is what we do, and we hold ourselves to the highest standards of professionalism in how we work with our clients and their projects.

Satisfaction

My Cons Ltd. gets many of our new client referrals by doing everything possible to ensure that every client is thrilled enough with our work to recommend us to others.